Upcoming Events

Check back again later for upcoming events

enCore is hosting a site tour of the Crow Butte ISR Uranium Operation – for more information contact info@encoreuranium.com

Past Events

Community Open House and Dinner

Community Open House and Dinner

Thank you to those who attended, we appreciate your support.

Please stay tuned for updates and the next events.

About

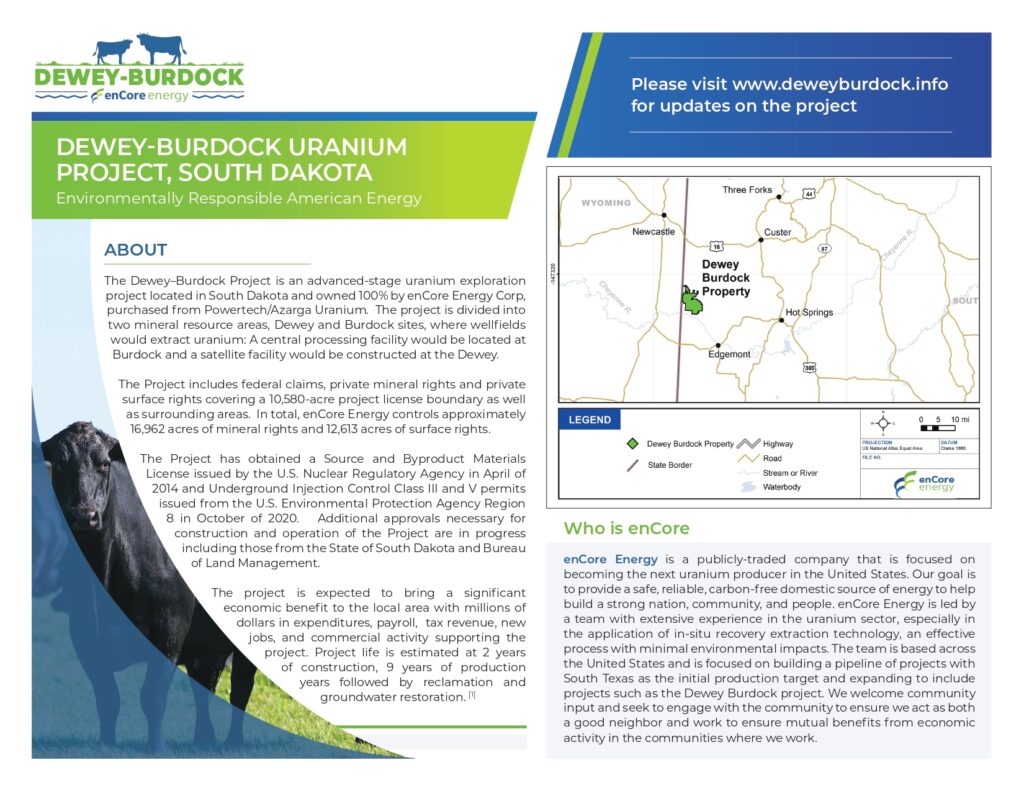

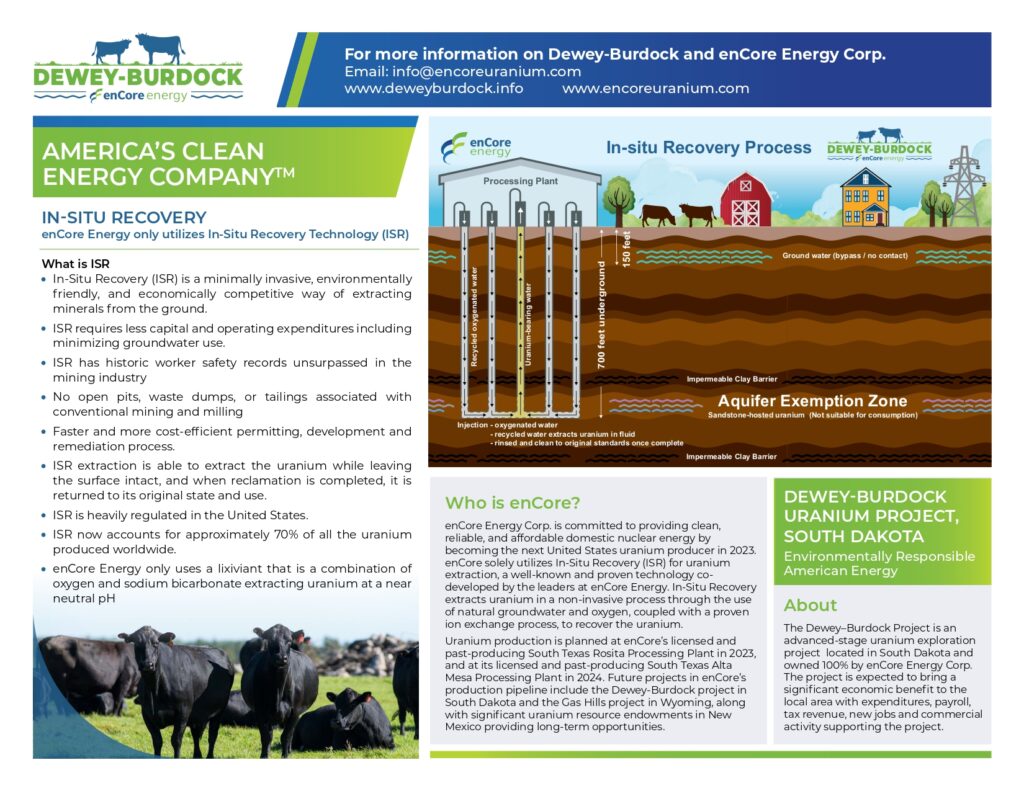

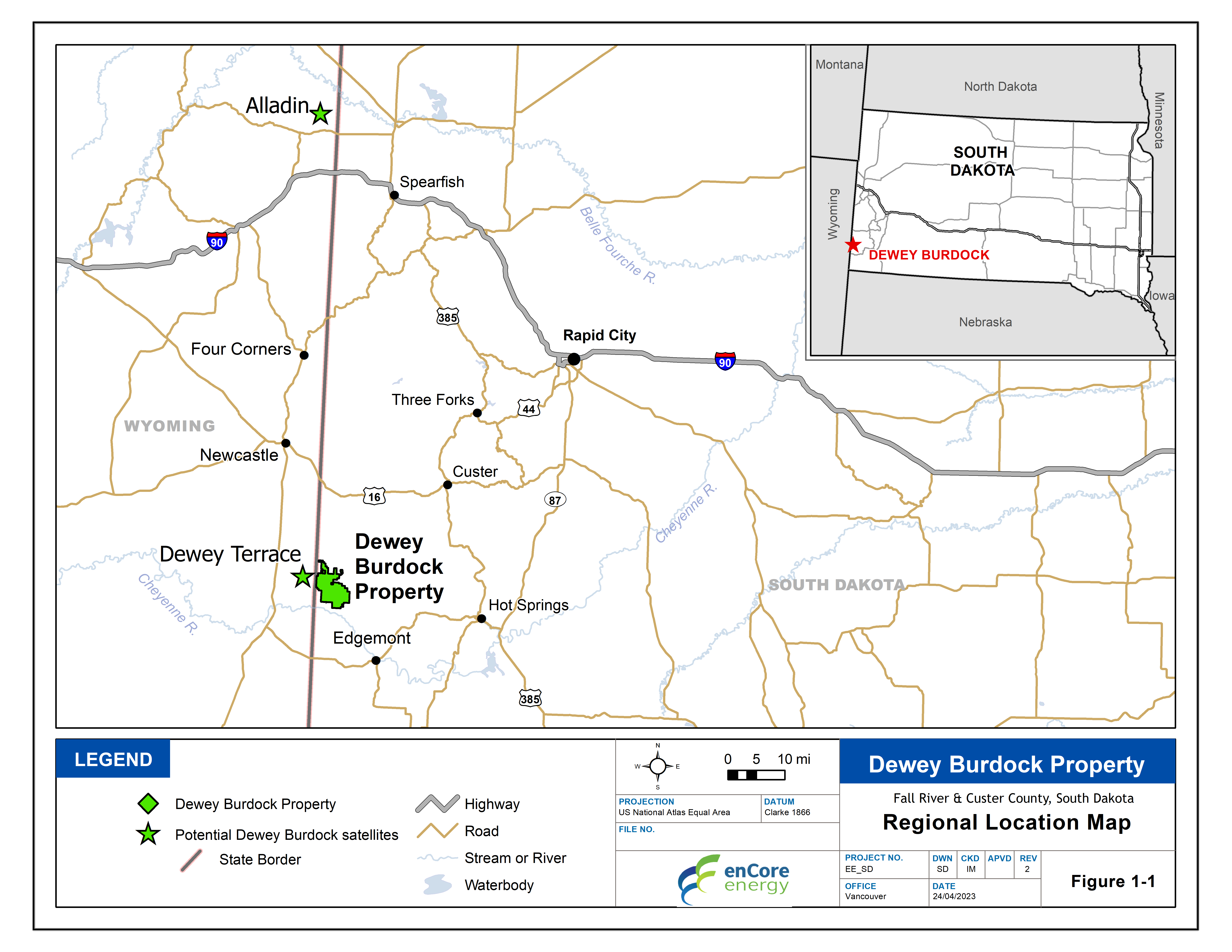

The Dewey–Burdock Project is an advanced-stage uranium exploration project located in South Dakota and owned 100% by enCore Energy Corp, purchased from Powertech/Azarga Uranium. The project is divided into two mineral resource areas; Dewey and Burdock sites, where wellfields would extract uranium. A central processing facility would be located at Burdock and a satellite facility would be constructed at the Dewey. Uranium mineralization is comprised of “roll-front” type uranium mineralization hosted in several sandstone stratigraphic horizons within the Inyan Kara Formation that are isolated from adjacent aquifers and therefore amenable to In-Situ Recovery technology.

The Project includes federal claims, private mineral rights and private surface rights covering a 10,580-acre project license boundary as well as surrounding areas. In total, enCore Energy controls approximately 16,962 acres of mineral rights and 12,613 acres of surface rights.

The Project has obtained a Source and Byproduct Materials License issued by the U.S. Nuclear Regulatory Agency in April of 2014 and Underground Injection Control Class III and V permits issued from the U.S. Environmental Protection Agency Region 8 in October of 2020. Additional approvals necessary for construction and operation of the Project are in progress including those from the State of South Dakota and Bureau of Land Management.

The project is expected to bring a significant economic benefit to the local area with millions of dollars in expenditures, payroll, tax revenue, new jobs, and commercial activity supporting the project. Project life is estimated at 2 years of construction, 9 years of production years followed by reclamation and groundwater restoration. [1]

[1] NI 43-101 Technical Report, Preliminary Economic Assessment. Dewey-Burdock Uranium ISR Project, South Dakota, USA, completed by Woodard & Curran and Rough Stock Mining Services (effective 3 December 2019)

Who is enCore?

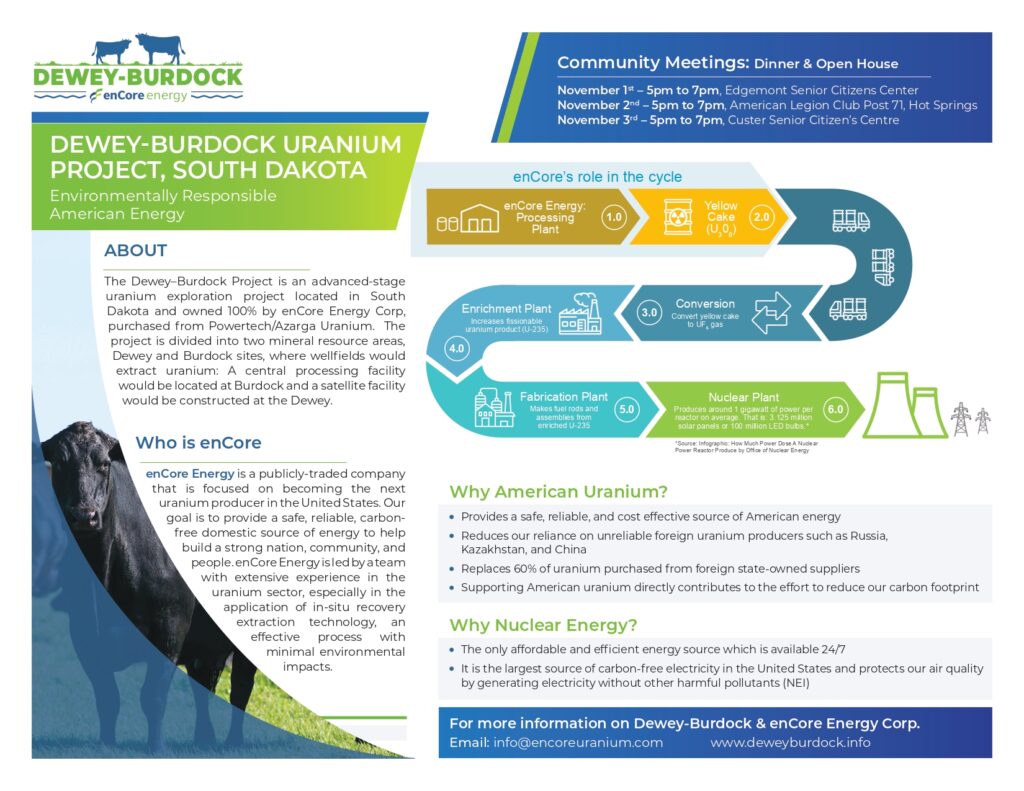

enCore Energy is a publicly-traded company that is focused on becoming the next uranium producer in the United States. Our goal is to provide a safe, reliable, carbon-free domestic source of energy to help build a strong nation, community, and people. enCore Energy is led by a team with extensive experience in the uranium sector, especially in the application of in-situ recovery extraction technology, an effective process with minimal environmental impacts. The team is based across the United States and is focused on building a pipeline of projects with South Texas as the initial production target and expanding to include projects such as the Dewey Burdock project. We welcome community input and seek to engage with the community to ensure we act as both a good neighbor and work to ensure mutual benefits form economic activity in the communities where we work.

History

Uranium was found in the Edgemont district, South Dakota, in 1952. Early discoveries were at the surface. Later drilling revealed deeper uranium deposits. In the mid 1970’s, Tennessee Valley Authority (TVA) bought a major interest in the area and made Dewey Burdock their main exploration target. Silver King Mines, project operator for TVA, had explored the property with over 4,000 drill holes. enCore Energy acquired the Dewey Burdock project from Azarga Uranium in 2021.

What is In-Situ Recovery? Will It Work at Dewey Burdock?

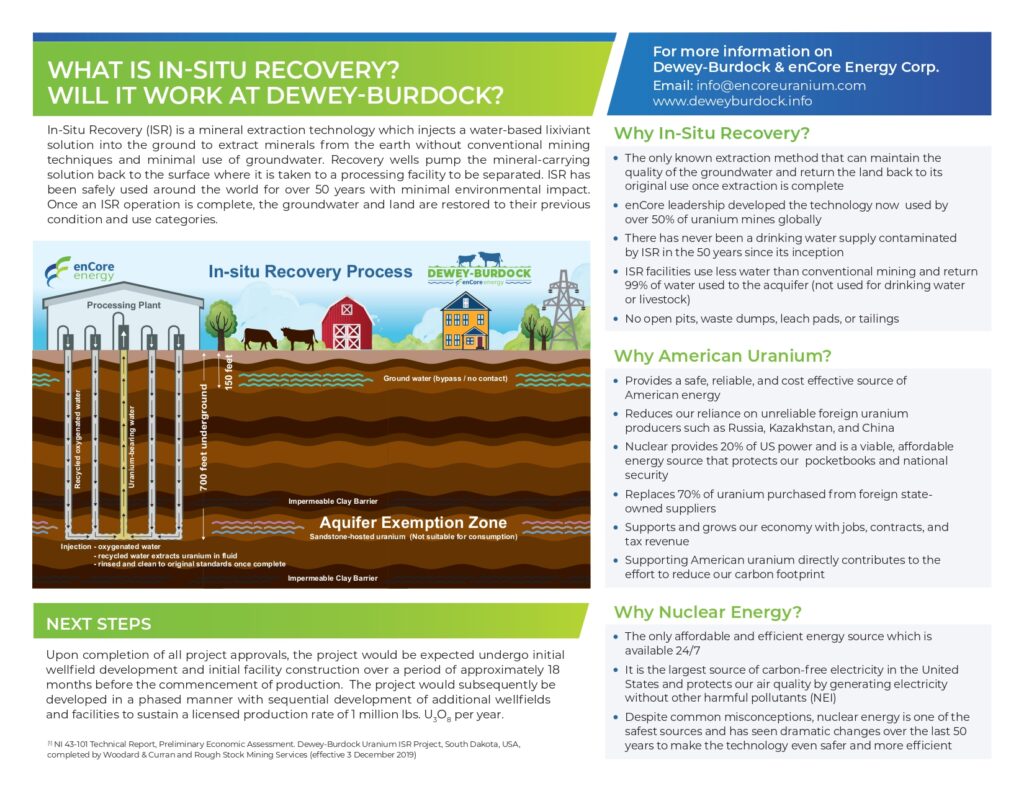

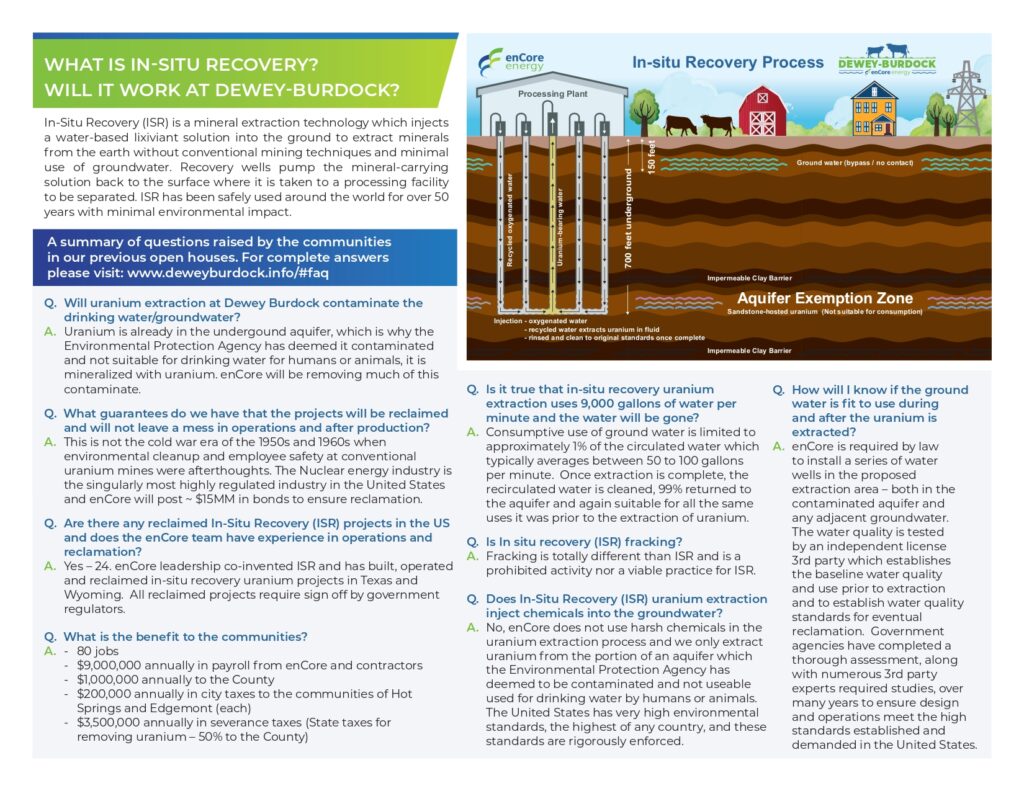

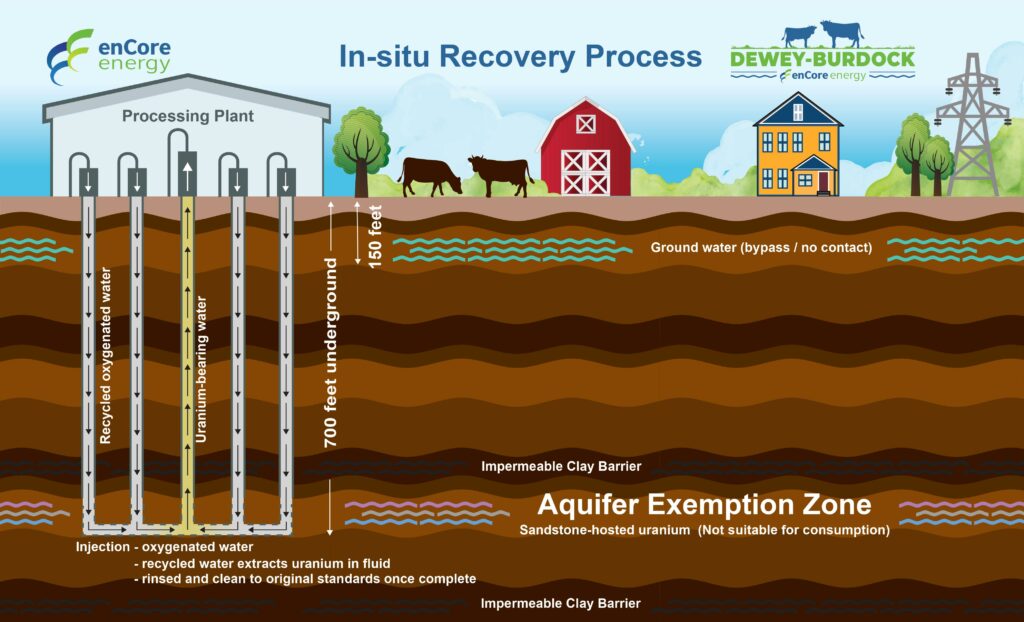

In-Situ Recovery (ISR) is a mineral extraction technology which injects a water-based lixiviant solution into the ground to extract minerals from the earth without conventional mining techniques and minimal use of groundwater. Recovery wells pump the mineral-carrying solution back to the surface where it is taken to a processing facility to be separated. ISR has been safely used around the world for over 50 years with minimal environmental impact. Once an ISR operation is complete, the groundwater and land are restored to their previous condition and use categories.

Why In-Situ Recovery?

- The only known extraction method that can maintain the quality of the groundwater and return the land back to its original use once extraction is complete

- enCore leadership developed the technology now used by over 50% of uranium mines globally

- There has never been a drinking water supply contaminated by ISR in the 50 years since its inception

- ISR facilities use less water than conventional mining and return 99% of water used to the acquifer (not used for drinking water or livestock)

- No open pits, waste dumps, leach pads, or tailings

- Unlocks the value of smaller mineral deposits

Analysis of the Fall River and Lakota hydro-stratigraphic unit, host for the mineralization, indicates that a range of ISR well pumping rates is suitable within the hydro-stratigraphic unit’s potential, and the unit’s transmissivity provide favorable conditions for ISR mining techniques.

Why American Uranium?

- Provides a safe, reliable, and cost effective source of American energy

- Reduces our reliance on unreliable foreign uranium producers such as Russia, Kazakhstan, and China

- Nuclear provides 20% of US power and is a viable, affordable energy source that protects our pocketbooks and national security

- Replaces 70% of uranium purchased from foreign state-owned suppliers

- Supports and grows our economy with jobs, contracts, and tax revenue

- Supporting American uranium directly contributes to the effort to reduce our carbon footprint

Why Nuclear Energy?

- The only affordable and efficient energy source which is available 24/7

- It is the largest source of carbon-free electricity in the United States and protects our air quality by generating electricity without other harmful pollutants (NEI)

- Bi-Partisan Support for Nuclear Energy in the US – for the first time in 48 years the Democrat platform supports nuclear: “We are not going to be able to achieve our climate goals if nuclear plants shut down. We have to find ways to keep them operating” - Energy Secretary Granholm

- Despite common misconceptions, nuclear energy is one of the safest sources and has seen dramatic changes over the last 50 years to make the technology even safer and more efficient

- “Uranium is being advanced as a “critical material” that is vital to America’s economic and national security.” - U.S. Department of Energy

Learn More About ISR & enCore

Benefits of Nuclear by enCore Energy

ISR: Environmentally Friendly Mineral Extraction

enCore: Drilling at Rosita in South Texas

Industry News

Frequently Asked Questions

Uranium is already in the undergound aquifer, which is why the Environmental Protection Agency has deemed it contaminated and not suitable for drinking water for humans or animals. This groundwater flows through sediments mineralized with uranium. enCore will be removing much of this contaminate. Commercial scale In-Situ Recovery (ISR) uranium extraction has operated in the US for almost 50 years, replacing conventional mining when conditions are appropriate. In these 50 years, no groundwater that has been designated as drinking water quality has been left in a contaminated state after final closure of the uranium extraction operations. Historically, following completion of uranium recovery, these operations have restored the underground aquifer to the same Federal use category it had before extraction began.

The United States Environmental Protection Agency (EPA) reviews every new ISR operation and only authorizes ISR operations in a very specific portion of underground aquifers, which the EPA classifies as contaminated for drinking purposes. Absolutely no activities are allowed outside of this small, designated area. United States Nuclear Regulation Committee (NRC) and State regulations require the company to return the water quality within this area to the same water quality use standards for which it was previously designated. Unlike most water wells, ISR operation wells are cased in heavy duty PVC piping, and once mining operations are complete, are filled with cement, to prevent fluid from entering any other water source or ground interval. During mining operations, groundwater is monitored with electronic and staffed controls as required by regulatory agencies which review the data monthly or quarterly. Any exception must be reported by the operator to these agencies immediately and corrective action immediately implemented.

This is not the cold war era of the 1950s and 1960s when environmental cleanup and employee safety at conventional uranium mines were afterthoughts. Licensing of Dewey Burdock ISR projects requires firm plans for not only development and operations, but also for total reclamation and restoration of both the site and the affected groundwater. enCore will be required to secure and post a total of approximately $15 million in bonds with the Environmental Protection Agency and Nuclear Regulatory Commission (NRC) to ensure sound reclamation. Only when the cleanup is approved, by both the State of South Dakota and the NRC, will the bonds be returned to enCore.

The Nuclear energy industry is the singularly most highly regulated industry in the United States which includes everything from uranium mining to the x-ray in the local hospital. There are no exceptions.

No, enCore does not use harsh chemicals in the uranium extraction process and we only extract uranium from the part of the aquifer designated by the Environmental Protection Agency as contaminated and that cannot be used for drinking water by humans or animals. We will use only gaseous oxygen and a bicarbonate. This is the equivalent of adding oxygen and baking soda to the contaminated underground aquifer, never touching drinking water. In the contaminated aquifer, the gaseous oxygen and bicarbonate within with water disolves the uranium minerals which exist as coatings on sand grains. We recover this groundwater, along with the dissolved uranium minerals, to our water treatment plant (similar to a home water softener only much larger) where the uranium is removed. Once the uranium is removed, the remaining water is then recycled and returned to the aquifer. Unlike conventional uranium mills, we do not use any acid to dissolve the uranium as they do in foreign countries. The United States has very high environmental standards.

There are 24 reclaimed uranium ISR projects in the United States, with enCore Directors having worked on 10 of these projects. enCore leadership co-invented ISR and has worked in the field for over 40 years building, operating and reclaiming in-situ recovery uranium projects in both Texas and Wyoming.

It is also important to understand that, typically, the reclamation of ISR projects is a continual yet finite process. As enCore works to extract uranium, it builds wellfields in specific patterns and then moves along the uranium resources over time as extraction proceeds. The Company then removes (from production) and reclaims exhausted wellfields as it completes the ongoing extraction process, thereby moving from one area to the next.

The nuclear energy industry is extremely regulated with safety and health regulations in place (including worker safety, air quality, radiation, water quality, spill management and more) that apply not only to on-site facilities but also extend to the transportation of the natural uranium product (yellowcake). Yellowcake is a dry powder. It is sealed in steel containers for transport to a conversion facility where it is transformed into an energy source for domestic and commercial use in the electric grid. It is shipped by tractor-trailer and regulated by the US Department of Transportation with extremely stringent requirements. Yellowcake shipments require advance written notification to the Nuclear Regulatory Commission (NRC) of the planned shipment including the content, quantity, and route to be followed. In addition, only a small number of trucking companies are certified to handle and transport yellowcake.

enCore is a North American company and all benefits stay within the United States. All uranium produced in Dewey Burdock will be sold only to domestic US power companies who use uranium to generate electricity which powers your home and business.

It is expected that activity from development, operations and reclamation will last approximately 20 years and will fuel our economy while creating jobs and strengthen local businesses. It is important to enCore that we provide opportunities for our youth to benefit from the extraction activities through jobs, education and training, thereby allowing our communities and families to grow and prosper.

This is not possible. The contaminated aquifer containing the uranium (and vanadium in this case) is situated in a geological structure that is contained in a unique, isolated location that allows for in-situ recovery extraction of uranium. The mineralized, contaminated aquifer is in no way connected to either the Cheyenne River or the drinking water supply for Hot Springs & Edgemont. These geological and hydrological facts can be verified by professors at the South Dakota School of Mines and the University of South Dakota. Clean water is vital to our collective lives, whether we are ranchers, miners, teachers or hospital workers, we all need it to survive.

During uranium extraction operations, large quantities of water from the contaminated underground aquifer circulate through the aquifer to dissolve uranium in the water. The uranium is then recovered in a water treatment plant and the water is reinjected into the ground. Consumptive use of ground water is limited to approximately 1% of the circulated water which typically averages between 50 to 100 gallons per minute. Once extraction is complete, the recirculated water is cleaned, 99% returned to the aquifer and again suitable for the same uses that it was prior to enCore’s involvement. It is important that enCore conserve and recycle water, and it is vital to the operations to maintain constant water levels for successful extraction of the uranium. It is imperative that we conduct ourselves as good corporate citizens and contribute in a positive way to the communities in which we work. We must leave a positive legacy which includes valuable infrastructure, water wells, power lines, clean drinking water and vibrant communities with high paying jobs and transferable skills for our youth.

In-situ recovery is not fracking. Fracking utilizes a totally different process than ISR. Fracking opens up preferential “fractures” in the subsurface using extreme pressure in order to provide conduits to extract hydrocarbons. Fracking is not a viable practice for ISR. ISR is designed specifically to avoid opening “cracks” and works by flowing water through existing sediments within an aquifer. Uranium minerals suitable for ISR extraction are deposited as coatings on sand grains and spread across both vertical and horizontal areas of the contaminated underground aquifer. ISR wells are designed to ensure that the water used in injection and extraction flows slowly and consistently through the aquifer in order to contact and dissolve the uranium minerals.

Prior to any extraction activity, enCore is required by law to install a series of water wells within the proposed extraction area – in the contaminated aquifer and within any adjacent aquifers. The water quality in each of these wells is tested by an independent 3rd party (a licensed laboratory) which establishes the baseline water quality and use category of these groundwaters prior to extraction. This establishes the use category enCore will be required meet in reclamation. Pre-extraction levels are established by independent experts, and in reclamation, these independent experts will also verify that pre-extraction level are returned to the aquifer.

Next Steps

Upon completion of all project approvals, the project would be expected to undergo initial wellfield development and initial facility construction over a period of approximately 18 months before the commencement of production. The project would subsequently be developed in a phased manner with sequential development of additional wellfields and facilities to sustain a licensed production rate of 1 million lbs. U3O8 per year.